Ron Rieger,

Egris' President, made a presentation on "Automated Strawberry Picking" to the

IEEE on October 7th, 2008.

IEEE Robotics and Automation Society proudly announces the

Buenaventura Section meeting notice for October 2008…

“Automated Strawberry Picking”

An interactive technical

review and forum to recommend future design and development.

Speaker:

Mr. Ronald Rieger, Rieger and Milliken Corp., Software Development

-

Systems

Integration / California State University Channel Is., Instructor

Date:

Tuesday, October 7th, 2008

Time: 6:30 p.m. pizza provided for meet

and greet; 7:00 p.m. Presentation

Location: California State University

Channel Islands (CSUCI)

50 University Drive, Camarillo, CA

93012

Broome Library room 1756

Directions:See following page with

map

RSVP/Contact:e-mail Ben Johnson at bjohnson@a-m-c.com

<mailto:bjohnson@a-m-c.com> .

Interactive Technical Review & Forum

This

special session is unique in that interdisciplinary technical experts are being

invited to participate in discussions and encouraged to make recommendations for

automating produce harvesting. Though the need increases yearly, an

assortment of researchers have been working on robotic automation of fresh

produce harvesting for decades. And yet, no viable, cost-effective

approach towards robotic mechanization has arisen. Costs of automating

harvesting is based on a number of issues including: picking speed, handling

considerations proportional to the delicacy of the produce, mechanization life

cycle/reliability, and other overall production overheads.

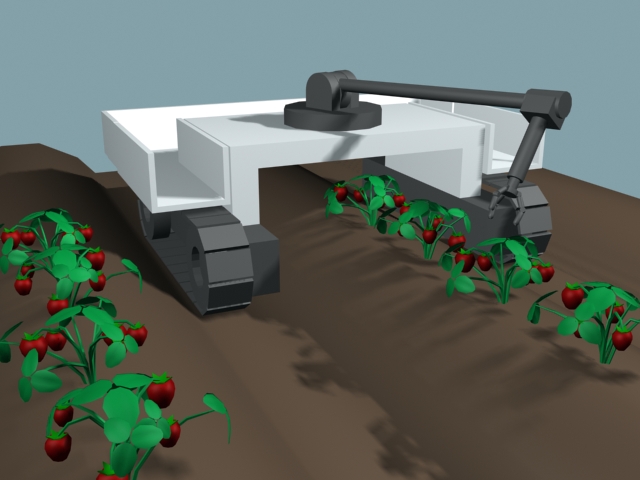

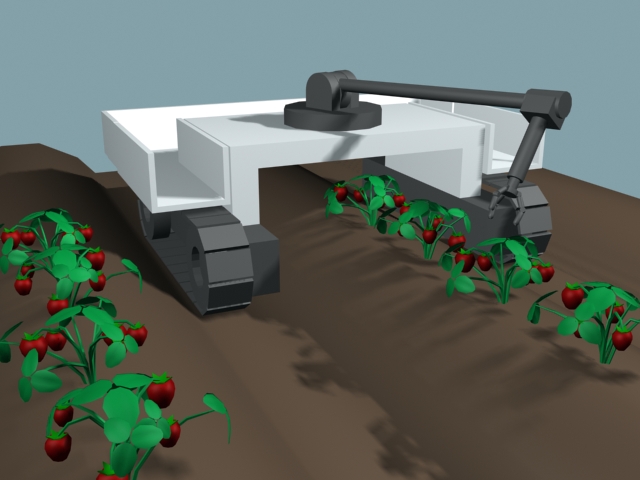

An open

research project to design and develop a robotic strawberry picker prototype has

recently been started. The initial team consists of students and faculty from

CSUCI and Egris personnel. The plan is to first design a functional

simulation and then to develop a field capable prototype. Assuming

success, production of the strawberry picker could theoretically be located

right here in Ventura County.

This is no easy task however. One of

the most difficult problems is simply to select an appropriate, interchangeable,

picking ‘hand’ mechanism specifically for strawberries. The challenge,

considered more a functional requirement and not just a highly desirable option,

is to have interchangeability of the ‘hand’ in order to harvest additional types

of row crops such as asparagus. With this in mind, an open review for

creative input of overall robot design considerations is being offered to the

local public.

Biography

Mr. Rieger has over 30 years experience in

high technology activities, management, consulting, and recently university

teaching. He is founder/proprietor of his own company and currently is

spearheading the setup of a separate non-profit for science education and

research. He has designed, implemented and/or been responsible for the

development of dozens of system and software products. Mr. Rieger has been

a key player in a variety of business management activities including strategic

and tactical business planning; new product design and development, performance

and/or data analysis, systems integration, and data capture/integration.

Mr. Rieger also has extensive experience in DBMS and telecommunications tool

design, development and use; embedded systems and other real-time or online

systems; specialized languages, and algorithm design and development applied to

many different integration activities. After consultation with various

video game companies, Mr. Rieger spearheaded the development and implementation

of a new multidiscipline minor in video game design and development. Mr. Rieger

currently has a patent pending for some of his pattern matching algorithms and

procedures.

The IEEE

Robotics and Automation Society is interested in both applied and

theoretical issues in robotics and automation. Robotics here is defined to

include intelligent machines and systems used, for example, in space

exploration, human services, or manufacturing; whereas automation includes the

use of automated methods in various applications, for example, factory, office,

home, laboratory automation, or transportation systems to improve performance

and productivity.

Robotics and Automation involves designing and

implementing intelligent machines that can do work too dirty, too dangerous, too

precise or too tedious for humans. It also pushes the boundary on the

level of intelligence and capability for many forms of autonomous,

semi-autonomous and tele-operated machines. Intelligent machines have

applications in medicine, defense, space and underwater exploration, service

industries, disaster relief, manufacturing, assembly, entertainment to name a

few. Within the foreseeable future, intelligent machines will expand and

migrate into many more and other non-traditional places. Robotics and

automation is on the move, embrace it!